Sahar Hoseini

Eindhoven University of Technology

Electronic Systems

Canon Production Printing

Research assignment: Real-time print artifact detection using deep neural networks |

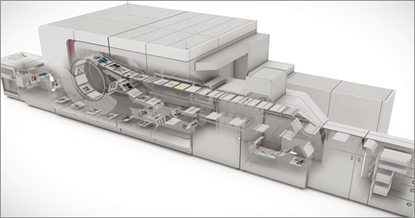

The need for accurate and high-print quality increased by increasing the demand for using inject printer in different areas especially printing documents and advertisements. One of the main concern for the printing industry is maintaining high print quality. Several types of faults may occur during the printing process which reduces the quality of the prints. The goal is to detect these artifacts and report them before print leaves the printer. There is an in-line scanner immediately after the printhead which can capture and store the image of the printed page. We aim to analyze these images with deep learning methods and report if there is any failure without interrupting the print process. The following figure shows one of the printers at Canon which is under study in this project. Since the deep learning method is quite new in the printing industry, there is no public dataset available. Therefore, the first step is to create a proper annotated dataset automatically. Then, developing a deep neural network to classify the existence of failure as well as localizing them on the printhead. |

Publications |

Personal information: |